The surface treatment of

PS (polystyrene) light guide plate has an important impact on its optical performance. Different surface treatment methods can change the light propagation characteristics, light uniformity and light transmittance of the light guide plate. The following are common PS light guide plate surface treatment methods and their impact on optical performance:

Frosted treatment:

Impact: The frosting treatment can increase the roughness of the light guide plate surface, causing light to undergo multiple reflections and refractions on the surface, thereby increasing the scattering of light and improving the uniformity of light.

Applicability: Suitable for occasions requiring better uniformity and scattering effects, such as lighting, etc.

Sand blasting:

Impact: Sandblasting can form tiny concave and convex structures on the surface of the light guide plate, causing diffuse reflection when light passes through, improving the uniformity and transmittance of light.

Applicability: Suitable for occasions requiring good light uniformity and light transmittance, such as flat panel displays, etc.

Polishing:

Impact: Polishing treatment can make the surface of the light guide plate smoother, reduce surface roughness, reduce light scattering and reflection, and improve light transmittance and propagation efficiency.

Applicability: Suitable for occasions requiring higher light transmittance and light transmission efficiency, such as optical instruments, etc.

Coating treatment:

Impact: Coating a transparent or coating with specific optical properties on the surface of the light guide plate can change the optical properties of the surface, such as enhancing light transmittance, reducing reflection, etc.

Applicability: Suitable for occasions requiring specific optical properties, such as anti-reflective coatings, anti-reflective coatings, etc.

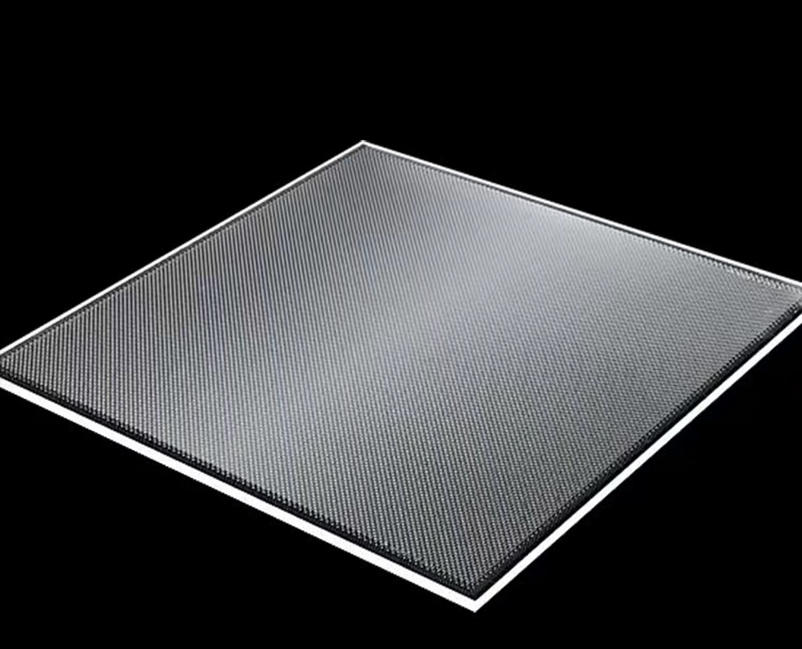

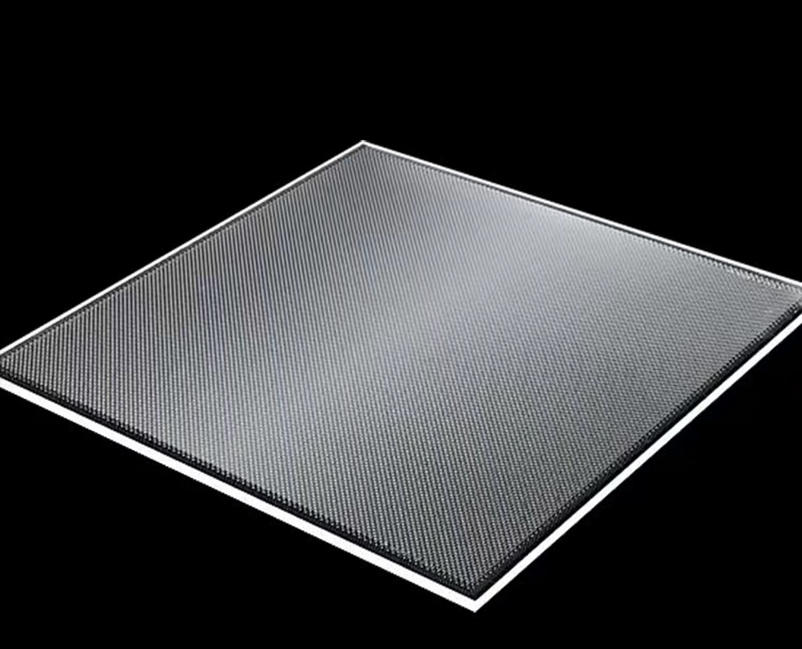

Texture processing:

Impact: Processing a specific texture on the surface of the light guide plate can control the propagation direction and angle of light to achieve specific optical effects.

Applicability: Suitable for occasions requiring directional light propagation or special optical effects, such as lenses, optical molds, etc.

Different surface treatment methods of PS light guide plate have different effects on its optical performance. By choosing the appropriate surface treatment method, the optical performance of the light guide plate can be effectively improved to meet the needs of different applications. In practical applications, appropriate surface treatment methods need to be selected based on specific optical requirements and technical conditions.

English

English 中文

中文 Español

Español