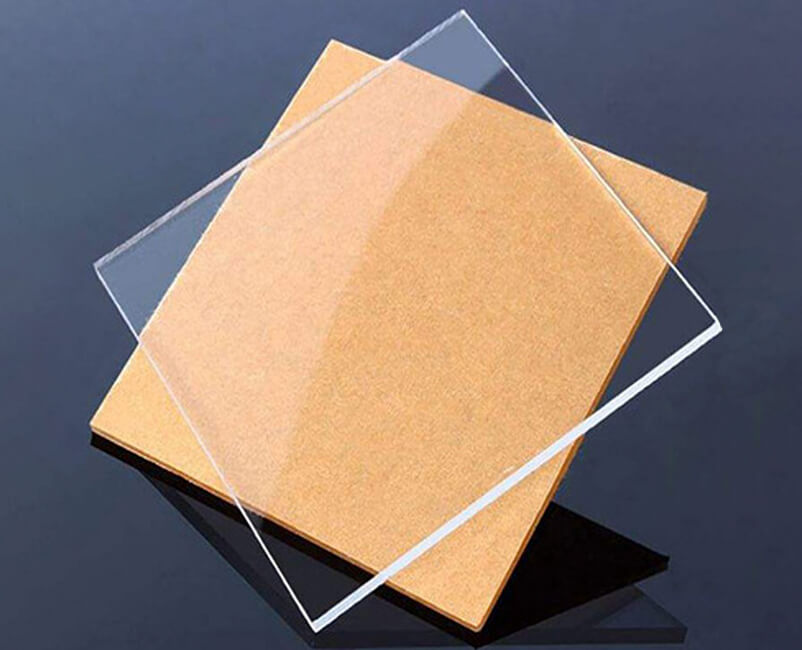

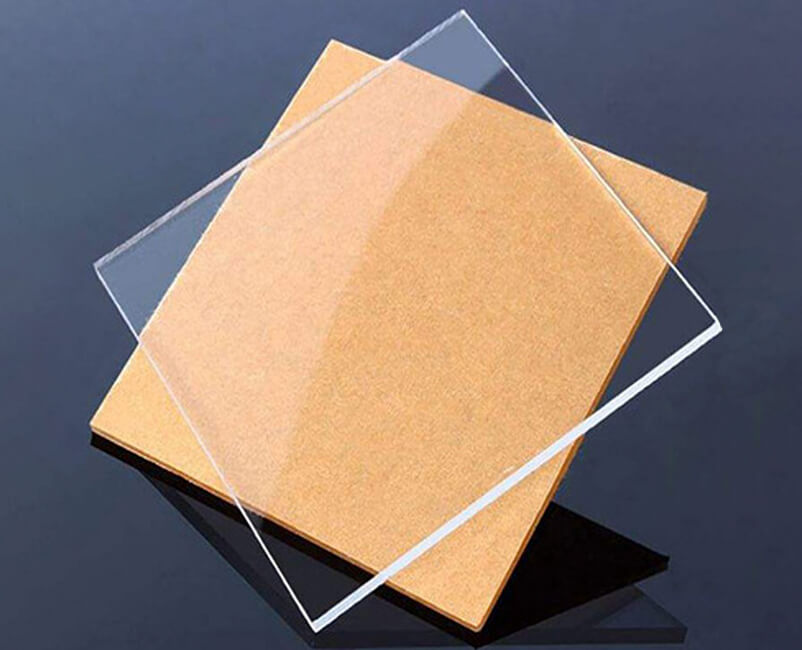

Clear Acrylic Sheet is a high-performance transparent material widely used in the fields of construction, advertising, transportation, lighting, etc. It is known for its excellent light transmittance, light weight and processing performance. However, in practical applications, especially in outdoor or strong light environments, people often care about whether it has good UV resistance and anti-yellowing performance.

First of all, ordinary transparent acrylic sheets without special treatment will undergo a certain degree of aging under long-term ultraviolet irradiation. The most obvious manifestation is the yellowing of the surface of the material, the decrease in light transmittance and the weakening of mechanical properties. This is because the energy of ultraviolet rays can trigger the breakage and oxidation reaction of polymer molecular chains, resulting in changes in the material structure. Therefore, if used directly under sunlight, ordinary acrylic sheets may turn yellow or even crack within a few months to a few years.

However, modern industry can significantly improve the weather resistance of acrylic sheets by adding anti-ultraviolet additives or surface coating treatment. The common "UV-resistant acrylic sheets" on the market are usually added with UV absorbers or light stabilizers (such as HALS, hindered amine light stabilizers) during the production process. These ingredients can effectively absorb or scatter UV energy, thereby slowing down the aging process of the material.

After this treatment, the transparent acrylic sheet can maintain its optical transparency and appearance color for a long time in the outdoor environment, and is widely used in outdoor advertising light boxes, bus stops, skylights, greenhouse covering materials and other fields. Some high-quality products can even guarantee no obvious yellowing in outdoor use for more than 10 years, and have excellent weather resistance stability.

In addition, some high-end products will also coat a layer of UV-resistant protective film on the surface of the sheet to further enhance its anti-aging ability. This double-layer protection mechanism can not only increase the service life of the material, but also reduce the performance degradation caused by environmental factors.

Of course, even after anti-UV treatment, acrylic sheets may still gradually age under extreme climatic conditions (such as high temperature and humidity, strong chemical corrosion environment). Therefore, when choosing a clear acrylic sheet for a specific scenario, its weather resistance level should be evaluated according to the actual use environment, and the technical parameters and service life description provided by the manufacturer should be referred to.

Clear Acrylic Sheet itself does not naturally have complete UV resistance and anti-yellowing capabilities, but through modern material modification technology and surface treatment processes, its performance in this regard can be greatly improved. For applications that require long-term exposure to sunlight, it is recommended to use high-quality UV-resistant acrylic sheets marked "UV resistant" or "with UV protection" to ensure the long-term stability of its aesthetics and functionality.

English

English 中文

中文 Español

Español