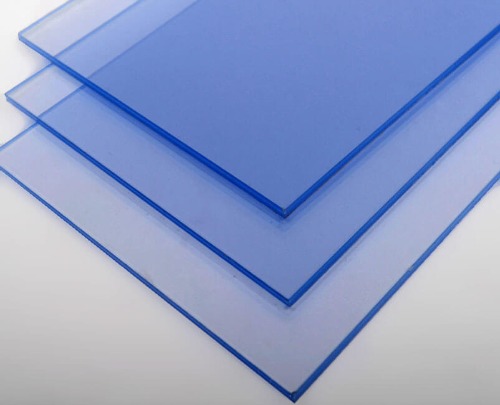

Clear polycarbonate sheets are made primarily from a polymer known as polycarbonate. Polycarbonate is a thermoplastic material that is derived from bisphenol A (BPA) and phosgene. The chemical composition of clear polycarbonate sheet can be described as:

Polycarbonate polymer: The main component of clear polycarbonate sheets is the polycarbonate polymer itself. It is a long-chain polymer formed through a condensation reaction between BPA and phosgene. The polymer chains consist of repeating units of carbon, oxygen, and bisphenol A.

Bisphenol A (BPA): BPA is a key monomer used in the synthesis of polycarbonate. It is a compound composed of two phenol groups connected by a bridging carbon atom. BPA provides the rigidity and strength to the polycarbonate structure.

Phosgene: Phosgene (carbonyl chloride) is a chemical compound used in the polymerization process to link the BPA monomers and form the polycarbonate polymer. Phosgene reacts with BPA to remove the hydroxyl groups and form carbonate linkages between the monomers.

Stabilizers and additives: Clear polycarbonate sheets may also contain various stabilizers and additives to improve their performance and durability. These additives can include UV stabilizers to protect against UV degradation, flame retardants to enhance fire resistance, and processing aids to improve the manufacturing process.

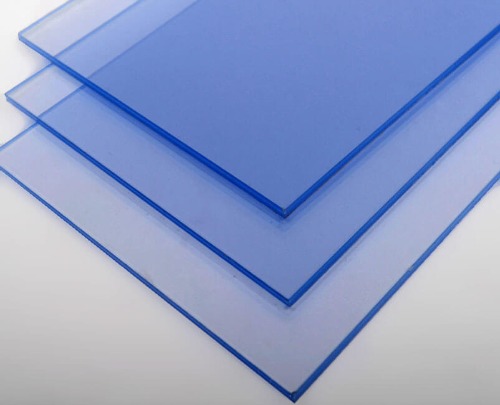

Polycarbonate is known for its excellent transparency, high impact resistance, and thermal stability. It is widely used in various applications such as windows, skylights, safety glasses, electronic displays, and protective barriers due to its desirable combination of properties.Meanwhile,Clear polycarbonate sheets are widely used in a variety of applications due to their unique properties and versatility. Here are some common uses of clear polycarbonate sheets:

Glazing and windows: Clear polycarbonate sheets are used as an alternative to traditional glass in glazing applications. They are lightweight, impact-resistant, and have high optical clarity, making them suitable for windows, skylights, and architectural glazing. Polycarbonate sheets can also be bent or curved to fit specific design requirements.

Safety and security barriers: Due to their high impact resistance, clear polycarbonate sheets are used in applications where safety and security are crucial. They are commonly used for protective barriers, safety shields, machine guards, riot shields, and vandal-proof windows in public spaces, banks, schools, and transportation vehicles.

Roofing and canopies: Polycarbonate sheets are utilized in roofing and canopies to provide natural light transmission while offering protection from the elements. They can be used in applications such as greenhouse roofing, pergolas, carports, and patio covers.

Electronic displays and signage: Clear polycarbonate sheets are used in electronic displays, such as LCD screens, touchscreens, and signage. Their optical clarity and resistance to shattering make them suitable for applications that require both visual appeal and durability.

Protective covers and enclosures: Polycarbonate sheets are commonly used as protective covers for machinery, equipment, and electrical components. They provide a transparent barrier that allows for visibility and inspection while protecting against dust, moisture, and impacts.

Medical and healthcare applications: Clear polycarbonate sheets find use in the medical field due to their impact resistance and ability to withstand sterilization processes. They are used for medical device enclosures, protective shields, isolation barriers, and safety goggles.

DIY projects and crafts: Polycarbonate sheets are popular among DIY enthusiasts and hobbyists. They can be easily cut, drilled, and shaped to create custom projects such as display cases, greenhouse panels, room dividers, and artistic installations.

English

English 中文

中文 Español

Español